What is it?

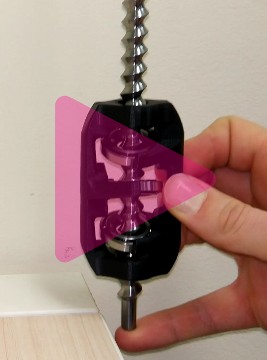

The ring screw mechanism is a mechanical device that achieves an almost frictionless screwing motion between a screw rod and a nut. It does this by means of a set of three or more rings that are mounted in ball bearings inside the nut. These rings rotate as the rod moves, so that the contact between each ring and the rod is a theoretically perfect rolling contact. The result is a movement that is almost completely frictionless, except for a small amount of friction within the ball bearings. The two videos above show how little friction there is in our first prototype.

What is it for?

The ring screw performs the same function as a ball screw, but is able to operate at much higher speeds. This means that a ring screw can be connected directly to the shaft of a modern high-speed brushless DC motor, whereas a ball screw would have to be connected via a reduction gear. Result: a simpler, more efficient linear actuator. Applications include robotics, aerospace, automation, etc.

What's new about it?

There are several examples in the patent literature of mechanisms involving rotating rings and screw rods. The special feature of the ring screw, which sets it apart from all previous mechanisms of this kind, is that it has been designed (using a branch of mathematics called screw theory) so that the contact between each ring and the rod is a theoretically pure rolling contact, not just at one or two points, but at every point along a line. This line contact allows larger forces to be transmitted; and the pure rolling motion means that the loss due to sliding friction is zero. The combination of large thrust force, no sliding, and high speed implies high power transmission at high efficiency.

Advantages

- Speed. Ring screws can operate at much higher speeds than ball screws.

- Efficiency. The efficiency of a ring screw is about the same as a ball screw, and therefore better than the combination of a ball screw and reduction gear.

- Flexibility. The nut can be 3D printed, giving you a lot of choice over its shape, the way it connects to other parts, and the material it is made from.

- Reliability. The ring screw mechanism is less likely to jam than a ball screw mechanism.

- Power to weight ratio. A linear actuator using a frameless DC motor built directly onto a ring screw rod would have fewer moving parts and weigh less than a similar actuator using a ball screw and reduction gear.

- Cleanliness. Neither the rod nor the rings need to be lubricated; so if the bearings are sealed then the rest of the mechanism can be clean.

- Easy assembly and disassembly. The rings simply slot into the nut, and the nut simply screws on and off the rod. No special tools are needed.

- Completely smooth operation. Preloaded ball screws exhibit a sharp momentary increase in resistance each time a ball emerges from the recirculation channel and re-engages with the rod. This does not happen with a ring screw.

A design detail: The contact between a ring and the rod is partially self-aligning; so if the rings are not quite in their correct positions, and the nut is slightly compliant (in order to apply the correct preload) then these errors will be corrected as the rod is screwed into the nut.

Disadvantages

- Ring screw nuts are bigger than ball screw nuts, and therefore need more space.

- Ring screws are new technology, and therefore not yet standard mechanical components, like ball screws, which are widely available off the shelf.

Test Results

- Efficiency 91%

- Tested at speeds up to 16,500rpm (the speed limit of the test rig, not the prototype).

These results are based on testing of a single prototype with a 4-ring nut, as described in Heijmink's thesis below. Only speed and efficiency were investigated.

Documentation

- technical document describing the ring screw (revised 2023)

- Elco Heijmink's MSc thesis describes how he tested the ring screw prototype

Patents

- Japanese Patent JP6400860(B2) (in Japanese)

- European Patent EP3295058(A1)

- US Patent US10364871(B2)

More....

- The ring screw was developed at the Italian Institute of Technology (IIT) by Roy Featherstone, with help from Elco Heijmink.

- IIT owns the ring screw patents. If you are interested in possible commercial applications then contact IIT and ask to be put through to their Technology Transfer Office.

- If you have technical questions then contact the inventor Roy Featherstone.